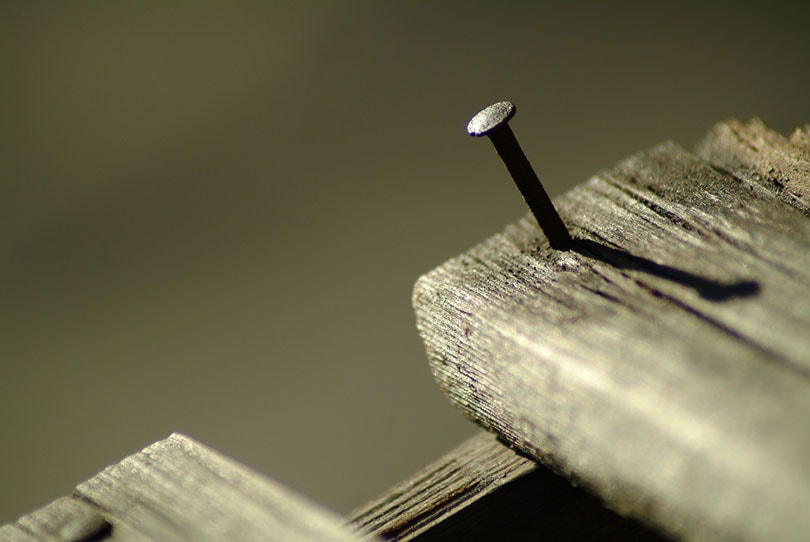

If you are a woodworker building a new workshop, it’s common to want to stock up on the supplies that you’ll need frequently. For example, woodworkers can never have enough nails, and there are several different types required to complete various tasks. If you are unsure of what types of nails you need, you’ve come to the right place. Keep reading as we look at several of the most popular types of nails used in woodworking and discuss when to use them.

The 9 Best Types of Nails for Wood

1. Roundhead Nails

- Uses: A strong bond

Roundhead nails are widespread sorts of nails used in woodworking, and you will find them in each and every woodshop. These nails are available in various lengths and thicknesses, but they all appear the same, with a prolonged pointy shaft and a lengthy flat head that is easy to strike with a hammer. These nails are not as desirable as other types, but they supply a lot of energy and will not slip or loosen over time.

2. Oval Head Nails

- Uses: Strong bond

Oval head nails are equivalent to roundhead nails, and the main big difference is the shape of the head, which is oval. The benefit of oval head nails is that it’s simpler to hammer them under the surface area, so they have a a lot more desirable physical appearance.

3. Casing Nails

- Uses: Finishing work

Kissing nails are like oval head nails, but it is even less difficult to generate them underneath the surface area simply because they have a tapered head rather of a stepped a single. Casing nails are equivalent to ending nails and are utilised in comparable situation, but they are a small bigger and provide a stronger bond.

4. Box Nails

- Uses: Flimsy wood

Box nails are related to roundhead nails, but they have a slender entire body, which will help prevent them from splitting the wood as you hammer them in, so they are perfect in situations in which the wood is dry, thin, or fragile. The draw back to box nails is that their thin dimensions means they don’t supply a powerful bond.

5. Finishing Nails

- Uses: Finishing work

Finishing nails are related to casing nails but are usually scaled-down and have an even narrower head that is effortless to travel beneath the floor for a more appealing physical appearance appropriate for finishing operate. Given that these nails don’t have significantly holding electrical power, woodworkers normally use them for mild woods for molding or trim.

6. Tacks

- Uses: Temporary fastener

Most people do not think about the tack a sort of nail, but which is what it is. It is basically an oversized round head with a quick physique. The massive head helps make it effortless to push in with your fingers rather of a hammer, so it’s a perfect short-term fastener, and it is one particular of the most typical nails in use.

7. Brad Nails

- Uses: For delicate wood

Brad nails are incredibly slender and delicate nails, used in fragile assignments like picture frames, birdhouses, and trim. It’s a fantastic selection when you’re concerned that you may well break up the wood, but they are not beneficial in tasks that call for a lot more energy.

8. Hardboard Nails

- Uses: For hardboard

Hardboard nails are specialized for use with hardboard, an engineered wood merchandise. While these nails work properly with the specialized wood, you won’t see them elsewhere.

9. Duplex Nails

- Uses: Temporary structures

Duplex nails are exclusive nails with two heads, a single under the other. You hammer the nail into the very first head for a snug bond. The component of the nail in between the 1st and second head sticks out from the surface, so it’s effortless to seize with pliers to pull out later on. You won’t discover these nails in several house structures, as they are largely used in momentary structures, where you want the energy of a very good nail with the capacity to eliminate it effortlessly.

What Are Nails Made Of?

Manufacturers use metal to make most of the nails in the United States. Metal is affordable and sturdy ample to supply great performance in fastening. Makers can also make nails from other materials, like stainless metal, which enhances strength and gives rust resistance. Copper can also get rid of rusting, but it’s softer than steel and much more high-priced. Economical nails might use iron or aluminum, but you’re much better off keeping away from these since they may not perform effectively.

What Are Galvanized Nails?

A galvanized nail is normally a steel nail coated with a layer of zinc. This coating produces a protective barrier that protects the nail from rust and corrosion, rising its all-natural lifespan. Woodworkers typically use galvanized nails on projects supposed for the outside, exactly where rain and other environmental aspects can quickly break down metal.

Summary

If you are a starting woodworker, a excellent source of roundhead, oval head, and finishing nails is a have to. You will use every single frequently, especially the roundhead, as you are finding out, so you can never have way too several. Thankfully, they are also relatively economical. As soon as you have more expertise and understand the restrictions of these nails, you can department out into the other kinds.

Featured Image Credit history: analogicus, Pixabay

Contents